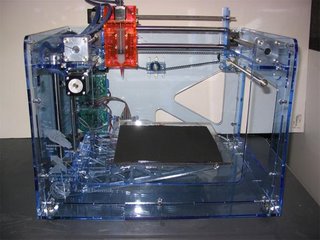

FAB @ HOME Project

FAB @ HOME Projecthttp://www.newscientisttech.com/article/dn10922-desktop-fabricator-may-kickstart-home-revolution.html

.

http://www.fabathome.org/wiki/index.php?title=Main_Page

.

It is coming, soon the revolution begins and we can all design and build the kits we desire at home!

.

For the same price as a 1986 Commodre C64 + Hard Disk + Printer cost in Europe during 1986, you can now join the advanced group of 3D modellers!

.

Soon we can trade files for models????????

.

many years ago Hobby Japan had run an article on a similar machine which worked on foam . There was no follow-on . But then the Fabhome article refers to 3D photocopiers and I remember using one of these many years ago. A shop near where I lived had one in free-access like a photocopier for braille-text photocopying. Unfortunately they had not enough customers so the machine was soon removed. However before that I had used it to produce engraved detail control panels for AMT Star Trek Enterprise bridge diorama. I used the AMT decals , copied them at high-contrast to get a pure black and white image and then run that through the 3D copier with great effect.

ReplyDeleteFor scratchbuilders like me this kind of machine would be a real bonanza !!!

JCC

JCC

ReplyDeletei think it would encourage a lot more people to share a lot more!

I think it would help transform the hobby and model market once these are as affordable as regular printers or lazer printers!

BD99

If you find fab@home impressive you might also want to take at look at the RepRap project out of the University of Bath in the UK...

ReplyDeletehttp://reprap.org

Their soon-to-be released machine is also open source, has a proper plastics extruder presently qualified for polycapralactone which can make usuable, hard objects. Whereas the fab@home machine costs $2,400 for parts, the RepRap Darwin is on track to cost no more than $400.

A spinoff of the RepRap project, Tommelise, is focussed on the American parts environment and uses somewhat different technology and a different control strategy. It's also an open source specification will let anybody with a few hand tools and primitive woodworking skills bootstrap themselves into 3D fabrication for about $150. Tommelise's extruder is qualified for polycapralactone and is presently being qualified as well for both high density polypropylene (HDPE, the stuff your plastic cutting board is made of) and polypropylene (HPP, the stuff your coffee maker and plastic electric kettle is made of). You can keep an eye on the Tommelise project at...

http://3dReplicators.com

Have fun!

plaasjaapie

ReplyDeletethat is cool, hope its not long before these projects get somewhere!

I am ok with glue, paint and imgaination, and can "get by" with a 3D package - but am rubbish at electronics and wires!

cheers

bd99